Table of Contents

What are Plate Underfloor Heating Systems?

Plate systems can be used with timber suspended floors where a screed underfloor heating system would not be suitable. A mechanical fixing is required for a wooden floor. The system requires insulation to be fixed between the joists, tight against the underside of the plate to prevent the downward passage of heat. Just because you have a wooden floor that doesn’t lend itself to a screed system doesn’t mean you have to miss out on all the advantages of underfloor heating.

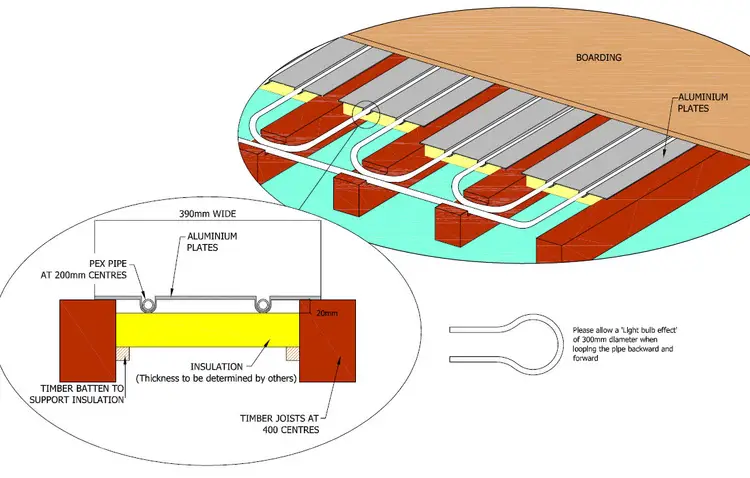

Typically the first preference is to cross batten at 400mm centres, however if you are experiencing height restrictions, fixing direct to the joists would be an alternative.

Aluminium plates are then fixed to the joists with 16mm PEX pipe neatly fastened within to aid the in the conductivity of the heat. They come in lengths of 1250mm and when laying the plates, you should leave a minimum of 50mm between each plate.

Notching is required in order for the pipe to pass over the joists. This must be carried out by a competent person. You should allow a 20mm x 20mm notch for each pipe.

What Plate Systems are Available?

There are a variety of underfloor heating systems suitable for Standard Plate installation both on a bespoke or kit form basis. Different systems are available for use with heat pumps or boilers and full specifications can be provided on request. Take a look at our underfloor heating FAQs for answers to many of the common questions you might have about the different approaches that can be taken.

Cross Battened Plate

This system is traditionally installed onto 20mm battens which lay at 90 degrees to the existing joists or on a decked floor at 400mm centres. The heat is transmitted in the same way as a Standard Plate system using aluminium plates to span the battens. The system requires insulation to be fixed between the joists as close as possible to the underside of the cross battens and plate to prevent the downward passage of heat.

Cross battening ensures that a uniform distance to suit the diffuser plates can be achieved and negates the need for notching.

Diffuser plates are 390mm wide which naturally leaves a gap in between the plates when laid at 400mm centres. This avoids any noise as the plates expand and contract with heat.

Cross battened plate systems are normally the preference for first and second floors however, on ground floors there is usually a ventilated void so pug would be preferable.

If plates are used, an alternative to the PUG system is routed insulation as this prevents air movement and heat loss.

What is a Cross Battened Plate on Timber Floor Underfloor Heating System?

Plate systems can be used where existing timber decking i.e. ply or chipboard cannot be removed in the instances where screed is not an option. Also best for floor finishes where mechanical fixing is required.

Cross battening ensures that a uniform distance to suit the diffuser plates can be achieved and negates the need for notching.

Diffuser plates come in lengths of 250mm. When laying the plates you should leave a minimum of 50mm between each length of plate. You should also ensure there is a 5 to 10mm gap between the plates where they are stapled to the joists and that no plate edges overlap.

Cross battened plate systems are generally the preference for first and second floors however, on ground floors there is usually a ventilated void so pug would be preferable.

If plates are used, an alternative to the pug system is routed insulation as this prevents air movement and heat loss.

Which Cross Battened Plate Systems for Timber Floors are Available in Scotland?

Many suppliers provide a variety of underfloor heating systems suitable for Cross Battened Plate installation. These systems are available for use with heat pumps or boilers and full specifications can be provided on request.

If your project demands a different approach, it is possible to use electrically heated underfloor systems to do the same job.